Thanks to their modular design, we create versatile machines designed to meet the most demanding needs. Since we have several accessories and options, we can offer you comprehensive solutions.

The most significant advantages of our machining centres are the flexibility of the X-longitudinal axis, that can be up to 12,000 mm useful length. Construction of the fixed table and mobile column will provide us with a broad range of operations, interpolating the movements of the 3 axes; it is possible to add a 4th axis to rotate the anchored parts. However, the most noteworthy element of our machines is the possibility of personalising them, adapting to each project's specific needs. Special operations such as fluo drilling and fluo tapping are a part of our daily life, having even automated lubricant and paste application systems.

A graphic way to check how our machining centres work is to see them in action. Our recordings of our CNC machines are at your service.

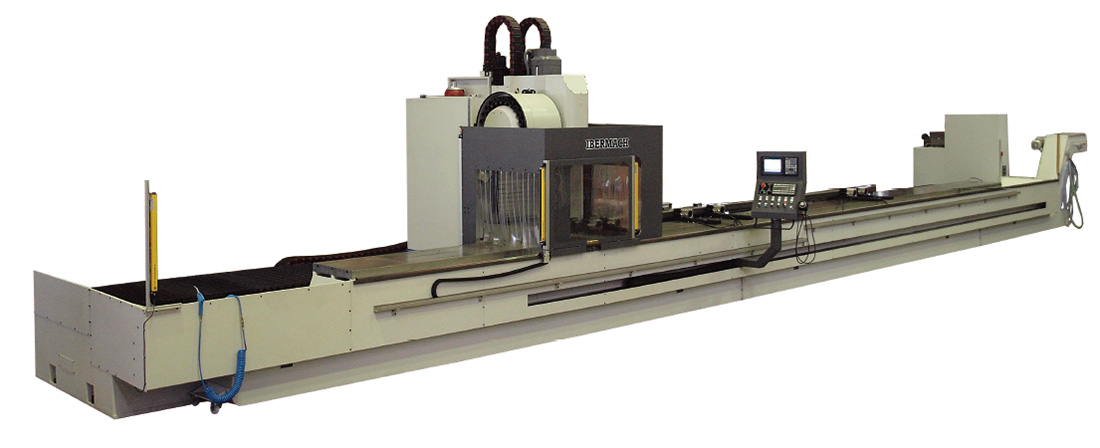

Experience in the industry has led us to develop CNC drilling and tapping machines that meet each project's needs. We have a firm commitment to meeting those needs. This is why we have worked to produce a flexible drilling and tapping centre regarding the length of the X-axis.

We believe in offering comprehensive to clients who, without having to make a large investment in a high-precision machining centre, seek to cover automatic tasks with a drilling, tapping or even milling centre.

Solutions for the manufacture of beams, profiles, frames, tubes and other parts with a great length that require drilling and tapping along all or part of their surface.

With our TH-40 tapping and drilling centre, we seek to provide quality for all companies, with no need to make a great economic investment, and always with the possibility of adapting to your needs.

A graphic way to check how our drilling and tapping centres work is to see it in action. Our recordings of our CNC machines are at your service.